CAM CLUTCH / Backstopper

| CHANGE PROCESS & CHARACTERS |

| CAM CLUTH (One way clutch) can overrn freely in one direction of rotation. Reverse rotation is instantaneously prevented by the automatic engagement of the clutch ( also called a backstop clutch or an one way clutch). A change for the better of clutches are as below. |

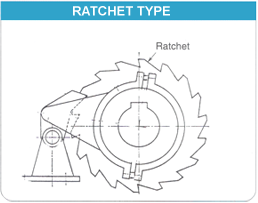

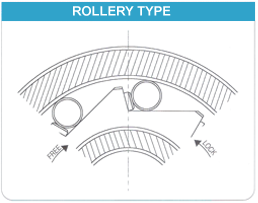

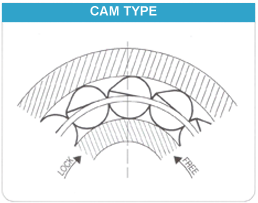

| A KIND & CHARACTER |

|

|

|

||

| Good point - Can see the operation of clutches. |

Good point - Easy to manufacture | Good point - Profitable at high speed and back rash protecion. |

||

| Bad point - High noise, lower durableness | Bad point - Machinery low efficiency at high speed operation. |

Bad point - Required high precision |

| SAM BO CAM CLUTCH |

| Cams of sam bo clutches was developed individually on 1992 year in Korea. Have been developed suitably for precision machinery and industrial machinery for the while. High performacne, long time life and high torque load will assure the high precision in your driving system. |

| ADVANTAGES |

| 1. MAX. LOAD & GREATER TORQUE CAPA. |

| The full complements of cams made special alloy steel provides the maximum number of load transmitting members per given diameter. Resultgreater torque capacity than the other roller clutches. |

| 2. LONG LIFE PERFORMANCE |

| In the roller clutch abrasion of the inner raceway always occur at the same point on each of the roller clutch lands. But the dimpling of cam clutches is distributed around the inner raceway, not concentrated. Therefore, this is assure the long wear resistances and offer long life performace. |

| 3. HIGH PERCISION (NO BACKLASH), SILENT OPERATION. |

| Cam clutches has many more load bering points because constantly changing contact point on both races. These has high precision without any back lash and silent operation |

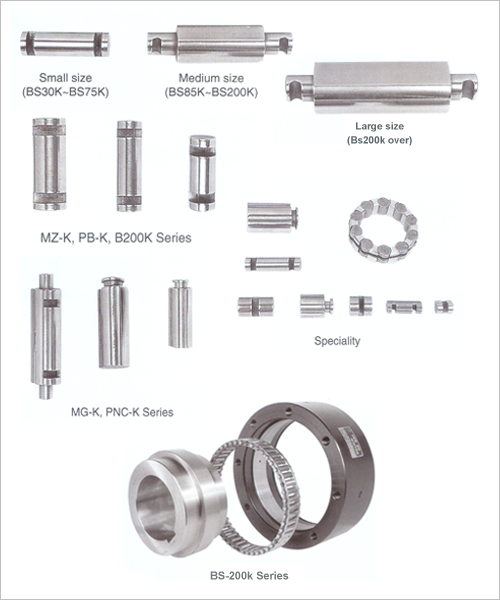

| PRODUTS OF SAM BO CLUTCH |

|

| CAM OF SAM BO CLUTCH |

|

| APPLICATION | ||

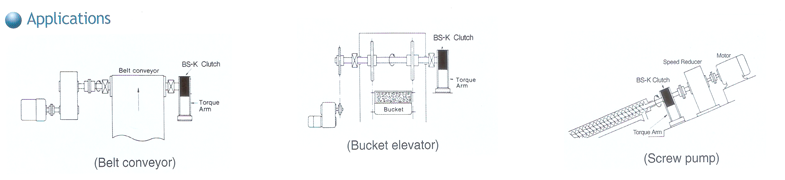

| 1. BACKSTOPPING |  |

|

In Backstop application, the clutch outer race is always stationary. The inner race of the clutch can overrun freely in one directon of rotation. Reverse rotaion is instantaneously prevented by the automatic engagement of the cam in the clutch |

| Applicatio : Converyor, Bucket Elevator, Lifter, Motor Wintch, Crane. |

|

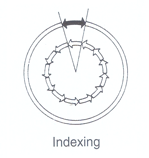

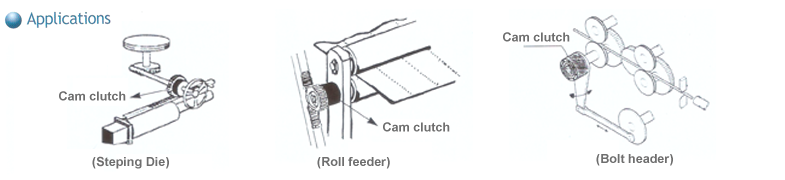

| 2. INDEXING |  |

|

In this mode of operation, reciprocating motion by rack & poinion gear and cylinder is imparted to the driving race of the clutch. Then, this motion is transmitted to the driven race in one directional intermittent motion |

| Applicatio : Cutting machines, Press, Auto-Puncher, Quilting Machines, Packing Machines. -(Transfer the material in the same stroked) |

|

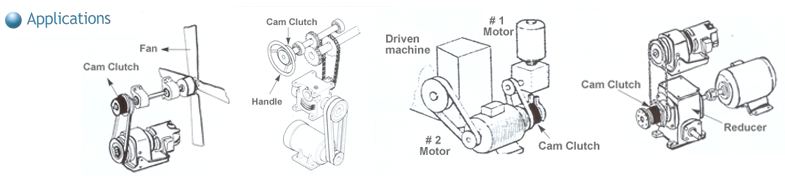

| 3. OVERRUNNING |  |

|

The output can rotate faster than the input is contisue to rotate if the input is stopped

Application EX : (1) If a large motor or turbine has to be run up to speed by a slow sleed stater motor, the use of a clutches enables the starter motor to be shut down. (2)If a clutches is interposed in a drive between a gear box and a large machine or fan, the clutch prevents any backdrive or damage to the gearbox in the event of power failure |

| Application : Large Blower(Fan), Calender, Kiln, Heavy lindustry Machinery, Crusher, Mill, Textile Machines, Printers, Agricultural machinery. |

|

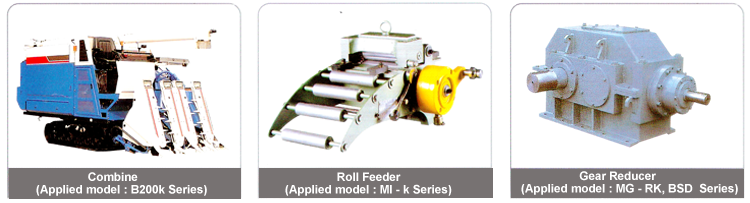

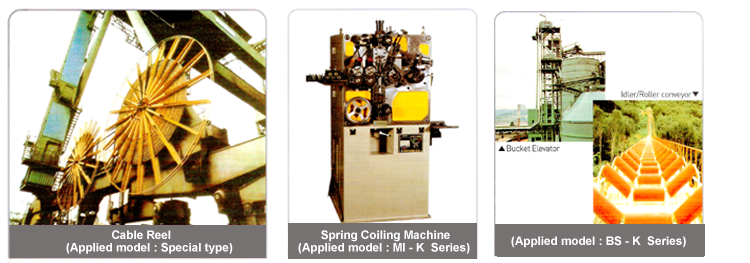

| Application example |

|

|